Buildings across the United States use 36% of the nation’s energy and generate 30% of greenhouse gas emissions, according to the U.S. Environmental Protection Agency (EPA). What’s more, about 30% of the energy used in commercial buildings is wasted.

It’s not surprising that the commercial construction industry is seeing a steady rise in sustainable and green building initiatives to address these challenges, with more projects adopting eco-friendly practices and energy-efficient designs. The U.S. Green Building Council (USGBC) says project registrations with the Leadership in Energy and Environmental Design (LEED) program increased about 20% between January 2017 and September 2022, when more than 45,630 projects and 7 billion gross square feet were registered.

How High-Performance Doors Support Sustainability Goals

High-performance doors offer several advantages over conventional overhead doors that support sustainability objectives.

Aligned with LEED Building Practices.

As a globally recognized symbol of sustainability leadership, LEED offers a framework for designing and operating healthy, efficient and cost-effective green buildings. High-performance doors help building owners maintain their LEED rating by using minimal energy to operate and by helping reduce the amount of energy needed to heat and cool the building.

For example, a food distribution facility advanced its sustainability mission by installing Rytec’s insulated fabric doors to help maintain its LEED Gold certification. With extra thermal barriers in the header, side columns and bottom bar, the doors helped the facility save 40% on energy while extending the refrigeration system’s lifespan.

Exceptional Thermal Performance.

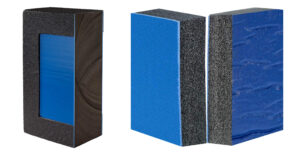

Some high-performance doors designed for cold storage are manufactured with energy-efficient materials, such as insulated panels, that have a high R-value (up to R40). These materials help reduce energy consumption and minimize energy loss when the doors are closed. Solid rigid rolling doors can be outfitted with insulated slats for added temperature control. Other high-performance doors feature durable, puncture-resistant, USDA-compliant, and tear-resistant materials, polymer-impregnated monofilament polyester fabric, and two- or three-ply thermal panels depending on environmental requirements. These materials make high-performance doors an efficient choice for buildings.

Some high-performance doors designed for cold storage are manufactured with energy-efficient materials, such as insulated panels, that have a high R-value (up to R40). These materials help reduce energy consumption and minimize energy loss when the doors are closed. Solid rigid rolling doors can be outfitted with insulated slats for added temperature control. Other high-performance doors feature durable, puncture-resistant, USDA-compliant, and tear-resistant materials, polymer-impregnated monofilament polyester fabric, and two- or three-ply thermal panels depending on environmental requirements. These materials make high-performance doors an efficient choice for buildings.

High Speeds for Less Air Exchange.

Building owners often install heavy panel sliding doors inside the building and sectional garage-style doors on exterior walls to guard against energy loss. Although these doors are insulated for a high R-value, they tend to be slow-moving, which increases air infiltration at the doorway.

High-performance doors open up to 100 inches per second – far faster than conventional overhead doors. For doorways with high traffic volumes, faster door operation trumps R-value when it comes to preventing energy loss and maintaining a productive environment. By opening and closing quickly, high-performance doors limit unregulated airflow between zones with different temperature requirements. By controlling airflow more effectively, these doors help reduce HVAC load and lower energy consumption.

Energy Efficiency Through Rapid Cycling.

Energy Efficiency Through Rapid Cycling.

A report from the Door and Access Systems Manufacturers Association (DASMA) found that high-speed doors become more efficient when cycled 55 or more times per day. At 75 cycles per day, 10% energy savings is realized. High-performance doors are usually specified for more than 75 cycles per day, demonstrating superior energy efficiency while meeting the demand for high-cycle operation in a building.

Lower Maintenance and Downtime.

When a slow panel door is struck by a vehicle, it can be misaligned or become inoperable, leaving the doorway exposed to significant energy loss. Many high-performance doors have a quick reset feature that returns the panel to its track and the door back into operation, minimizing downtime and air ingress. Plus, the lightweight design of high-performance doors puts less strain on operating parts and requires lower horsepower drives. As a result, downtime and maintenance costs on high-speed doors are minimal.

Compliance with the Latest Energy Codes.

When architects are specifying doors and building managers are updating their infrastructure, using high-performance doors can help them comply with energy codes.

In 2014, high-performance doors received thermal performance recognition from the American National Standards Institute (ANSI), the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), the Illuminating Engineering Society (IES) and the International Code Council (ICC).

As part of the formal assessment and review process, ASHRAE evaluated and tested doors to determine performance expectations and establish a standard. The qualities and performance characteristics of Rytec’s PredaDoor® NXT® model set the standard for high-speed fabric doors.

Long-Lasting Materials for Less Waste

High-performance doors are engineered with long-lasting components that significantly reduce waste and material consumption over their lifecycle. Because these components last longer, fewer parts need to be manufactured and replaced, which means reducing the amount of discarded materials that are sent to landfills.

High-performance doors represent a measurable, high-impact way to support facilities’ sustainability initiatives. Contact us today to learn how high-performance doors can help your building achieve its sustainability goals while improving efficiency and productivity.

Have Questions?

Let’s talk about how high-performance doors can help enhance your facility. Get connected with your local Rytec Regional Sales Managers.