In industrial environments with combustible materials, flammable liquids, vapors, or explosive dust, the overhead doors you use are critical to maintaining safe and efficient operations. High-performance doors are a great option for hazardous areas, because they can lower risk while maintaining safety and productivity.

They offer more than access control – they reduce risk, help meet regulations and ensure operational excellence. By combining specialized components and tailored engineering, high-performance doors keep your facility operating efficiently without compromising safety.

What Is a Hazardous Location?

A hazardous location is any area where the risk of fire or explosion exists due to the presence of flammable gases, vapors, liquids or combustible dust. These environments are typically grouped into two categories:

- Class 1 – Liquids: Refineries, adhesives, chemicals, pharmaceuticals and ethanol plants

- Class 2 – Dust: Grains, nuts, coal/carbon, wood and polys such as ethylene, carbonite, urethane, etc.

Each class requires specialized door components to withstand extreme conditions and reduce the risk of accidents.

In either case, areas adjacent to the classified location, such as the opposite side of the door opening, might also be considered hazardous. Rating or derating these adjacent areas is the responsibility of the authority with jurisdiction over that area.

Key Features to Reduce Risks

Doors used in hazardous environments often require special alterations and components designed to meet stringent industry and safety standards. Because of this, most standard doors aren’t a good fit for these locations because they can’t adequately protect people and equipment.

Unlike standard overhead doors, high-performance doors can be reinforced by incorporating a range of special components to enhance operational safety, helping reduce the risk of combustible reactions when installed and used correctly.

Intrinsically safe activators. These door activation options are engineered to operate without producing sparks or excessive heat, reducing the chance of ignition. These activators can include automatic activation devices, such as motion and presence detectors for hands-free door opening and closing. Manual activation options, such as push buttons and pull cords in properly rated enclosures, are suitable for hazardous areas with low or predictable traffic levels.

Photo eyes are another safety feature used to assess the area around the door to determine if it is safe to close or needs to be opened. If their light beams are blocked or interrupted, the door will not close.

Intrinsically safe internal components. Intrinsic safety is accomplished by using specially designed “electrical barriers” that reduce the electrical current to levels that can’t produce sparks, arcing or heat. These can include limit switches, positioning devices, bottom bars, electronics, and controller enclosures, all designed to meet area classification requirements. In addition, Rytec’s next-generation System 4® door controller provides enhanced, assured performance by enabling precise door positioning without mechanical limit switches.

Anti-static elements. From brush seals to 2- or 3-ply Rylon® panels, these features help dissipate static electricity that could otherwise trigger combustion in dusty or vapor-heavy environments.

Together, these features allow high-performance doors to deliver speed and efficiency while effectively mitigating the safety risks of hazardous applications.

What to Expect When Specifying Doors

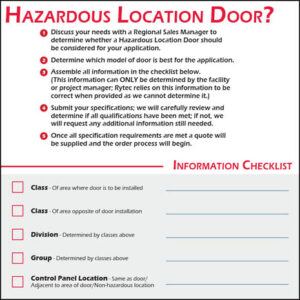

Purchasing a high-performance door for a hazardous location is a multi-step process designed to ensure safety and compliance. Every hazardous location door must undergo a thorough, site-specific evaluation before it can be quoted or specified. This process requires close collaboration between the facility or project manager and the door manufacturer to determine which door is right for your application.

- Contact a Regional Sales Manager to determine whether a hazardous location door is appropriate for your application.

- Identify the best door model based on your facility’s operational needs and environmental conditions.

- Complete an information checklist, which must be confirmed by the facility or project manager.

- Submit specifications for review, allowing the door manufacturer to confirm that all qualifications have been met.

- Receive a quote once all requirements have been satisfied to begin the order process.

This process might take more time on the front end than specifying a standard door, but it will ultimately help protect people, equipment and products in demanding industrial environments.

[DOWNLOAD YOUR CHECKLIST HERE]

For operations that handle volatile materials or combustible dust, working with an experienced door manufacturer can help ensure that every door supports both productivity and protection. That’s where Rytec’s experts can help. See the features that make Rytec the safe choice in high-performance doors. Or contact us to ensure the safety of your facility and staff.

What to Expect When Specifying Doors

Purchasing a high-performance door for a hazardous location is a multi-step process designed to ensure safety and compliance. Every hazardous location door must undergo a thorough, site-specific evaluation before it can be quoted or specified. This process requires close collaboration between the facility or project manager and the door manufacturer to determine which door is right for your application.

- Contact a Regional Sales Manager to determine whether a hazardous location door is appropriate for your application.

- Identify the best door model based on your facility’s operational needs and environmental conditions.

- Complete an information checklist, which must be confirmed by the facility or project manager.

- Submit specifications for review, allowing the door manufacturer to confirm that all qualifications have been met.

- Receive a quote once all requirements have been satisfied to begin the order process.

This process might take more time on the front end than specifying a standard door, but it will ultimately help protect people, equipment and products in demanding industrial environments.

For operations that handle volatile materials or combustible dust, working with an experienced door manufacturer can help ensure that every door supports both productivity and protection. That’s where Rytec’s experts can help. See the features that make Rytec the safe choice in high-performance doors. Or contact us to ensure the safety of your facility and staff.

Have Questions?

Let’s talk about how high-performance doors can help enhance your facility. Get connected with your local Rytec Regional Sales Managers.