Years ago, traditional sectional doors were the only overhead door options available for commercial buildings. Since then, door options have evolved to meet customers’ ever-changing needs. Now, building operators and owners can choose between many kinds of doors, from conventional overhead doors to high-speed, high-performance doors.

Years ago, traditional sectional doors were the only overhead door options available for commercial buildings. Since then, door options have evolved to meet customers’ ever-changing needs. Now, building operators and owners can choose between many kinds of doors, from conventional overhead doors to high-speed, high-performance doors.

Conventional Overhead Doors

For decades, sectional commercial doors were the industry standard for many businesses and buildings. They’re created from panels that move along metal tracks, and they can be customized to fit many sizes of openings.

High-Speed and High-Performance Doors

These doors add functionality and features to conventional doors, improving speed, longevity and performance. High-performance doors are designed to withstand a minimum of 100 cycles per day and open at a minimum of 20 inches per second, far faster than traditional doors. High-speed doors – a specialized type of high-performance door – feature even higher minimum speeds of 32 inches per second (opening) and 24 inches per second (closing). Whether high-speed or high-performance, both improve operational activity in nearly any application or commercial setting.

The Differences Between Conventional and High-Speed Doors

Air Exchange

A door opening typically experiences air movement through the opening at a rate of approximately 3 feet per second. The longer the door is open, the more air is exchanged between the two areas.

Conventional overhead doors are slow moving and allow significant air movement between areas, which can lead to energy loss and higher energy bills. However, high-performance/ high-speed doors move quickly to reduce air exchange and provide significant energy savings.

In 2014, high-speed doors were recognized for their thermal performance by the American National Standards Institute (ANSI), the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), the Illuminating Engineering Society (IES) and the International Code Council (ICC). This recognition meant acknowledging the energy efficiency of the doors and incorporating minimum standards into the code for high-speed doors.

The International Energy Conservation Code (IECC) and ASHRAE 90.1 include a maximum allowable air infiltration rate of 1.3 cubic feet per minute per square foot of door area (cfm/sf.) for high-speed doors. Further, ASHRAE 189.1 includes a maximum allowable U-factor (the rate at which a door transmits non-solar heat) of 1.2 BTU/hr-degF-sf for high-speed doors operating at a minimum average of 75 cycles per day.

Partly due to these regulations, high-speed doors are proven to deliver 10% more energy savings than conventionally operating insulated doors. Conventional doors simply can’t meet these same standards for energy efficiency or savings.

Vehicle and Equipment Impact Resistance

High-speed/high-performance doors often can withstand impact from equipment and vehicles, unlike conventional overhead doors that are typically damaged during a collision.

Many fabric high-performance doors have a self-repair/re-feed design that doesn’t require tools. On many aluminum high-performance doors, damaged and impacted slats can be quickly removed and replaced, allowing for continued operation. This impact resistance helps minimize downtime and reduces the need for additional staff to repair or provide building security during maintenance. Traditional doors don’t have self-repair options and thus require additional time for maintenance and repair.

Maintenance Costs

Sectional doors have more moving parts, including springs, rollers and hinges, that can deteriorate or break down over time, requiring more maintenance and downtime.

High-performance doors have lower maintenance costs because they’re made with proven industrial-strength components and don’t have limited cycle torsion springs to replace. They’re built with 460/230/208-volt industrial motors and a heavy-duty industrial gearbox for easy, smooth opening and closing. In addition, the AC drive controller used with high-performance doors provides a soft start/soft stop to help reduce brake and motor wear over time.

Speed

Conventional doors need to be opened manually or by electric motor. However, both methods can be challenging because the doors are often heavy, which makes it difficult to open them smoothly and efficiently.

High-speed/high-performance doors are lighter weight, improving traffic flow and building security with fast opening and closing speeds. For example, the Spiral® FV® can open up to 100 inches per second, which helps prevent unwanted vehicles, people and debris from entering the building. Conventional doors will never match these opening (and closing) speeds.

Cycle Life

Unlike high-performance doors, bi-fold and conventional doors are not designed for high volume usage. However, many types of high-performance doors are designed to operate 60 times an hour, and up to 1,000 times or more a day.

Bi-fold and conventional doors use torsion springs that limit the number of door cycles, while typical high-performance doors do not use torsion springs to extend cycle life. Torsion springs used in bi-fold and conventional doors typically have a life of 25,000 to 100,000 cycles, whereas, high-performance doors can operate for millions of cycles with proper maintenance.

High-Speed/High-Performance Doors Have the Edge Over Conventional Doors

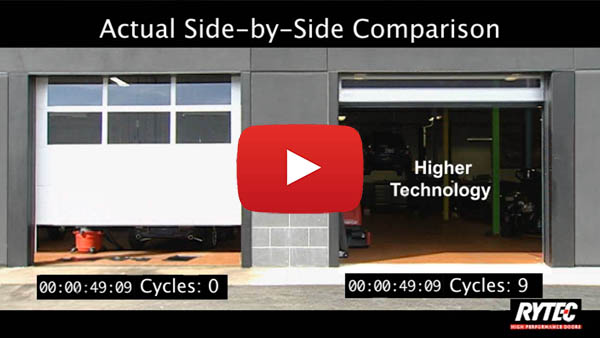

See the benefits of high-speed, high-performance doors with every cycle in this real-world side-by-side comparison of an old-fashioned conventional garage door versus the Rytec Spiral® FV®.

High-performance/high-speed doors are built to provide exceptional performance in virtually any environment. Contact us today to discuss how Rytec doors can address all of your building’s needs.