Rytec’s Sure-Seal® door is designed for AS/RS applications. It can be tightly integrated with warehouse automation systems for maximum efficiency.

Rytec’s Sure-Seal® door is designed for AS/RS applications. It can be tightly integrated with warehouse automation systems for maximum efficiency.

High-performance doors used in cold storage should be inspected quarterly. Here are key areas you should pay attention to during your inspections.

In manufacturing facilities, doors must be reliable for the factory to maintain peak efficiency. Here’s how high-performance doors help.

Cold storage facilities are getting taller to reduce their real estate footprint. So are the high-performance doors used to keep them running efficiently.

High-performance doors deliver reliable performance. That’s because they’re built for longer life expectancy than conventional doors. Here are 4 examples.

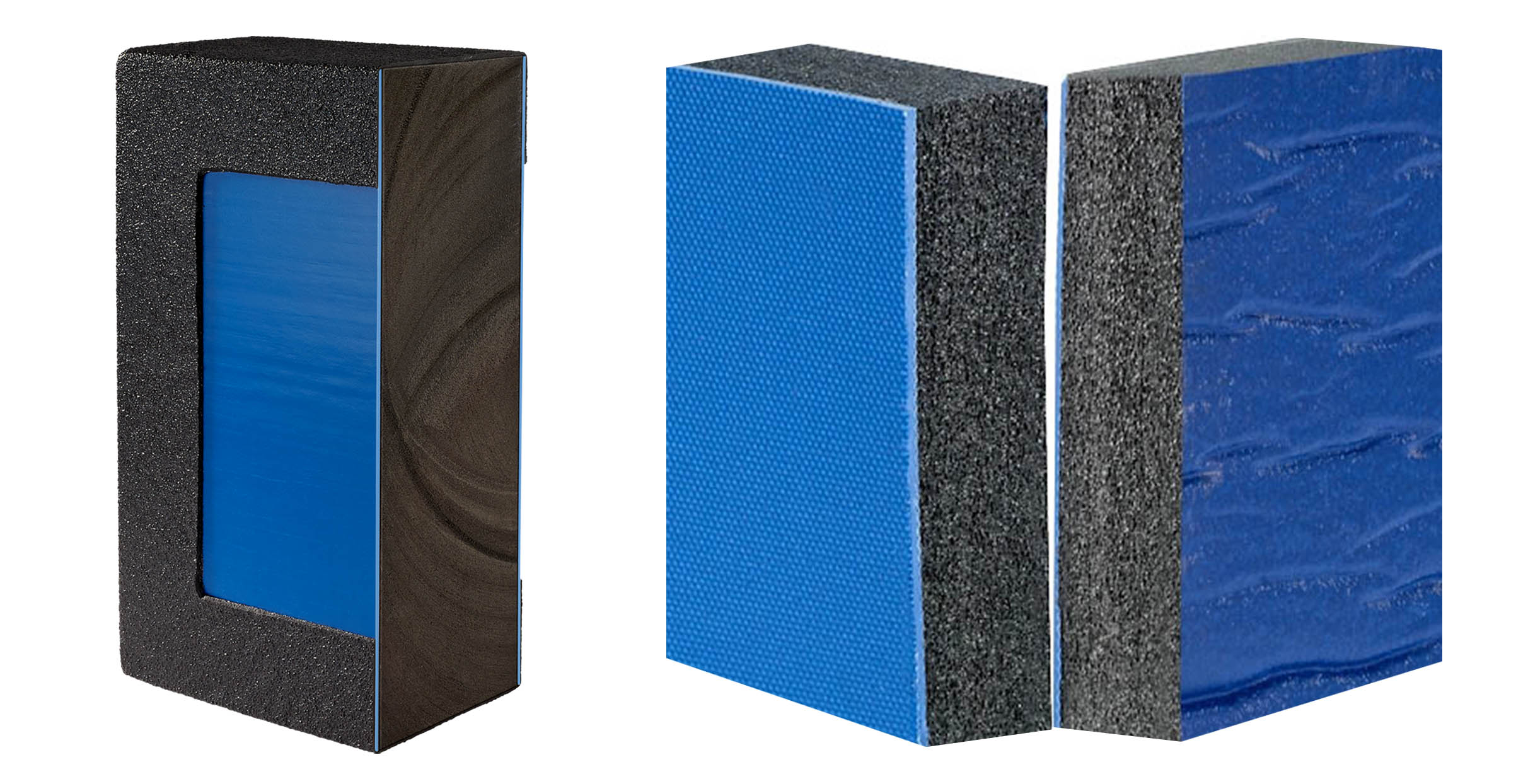

Understanding the R-value of doors is critical in the cold storage industry, where minimizing heat loss and maximizing energy efficiency is a must.

If you’re using traditional overhead doors in your cold storage or food production facility, you may be experiencing significant energy loss.

High-performance doors help loading docks keep up with today’s peak demand cycles. Here are door types used in this environment and common features.

High-performance doors provide food processing and distribution facilities with reliability, speed and efficiency to meet today’s growing consumer demand.

Several styles of high-performance doors can help manage a variety of cold storage conditions. Here’s how to select the right one for your needs,

June is National Safety Month! Learn how high-performance doors with advanced safety features help reduce workplace injuries and support safer environments.

For facilities with automated storage and retrieval systems (ASRS), high-performance doors are critical to maximizing energy efficiency and performance..