High-performance doors safeguard cold storage and food and beverage facilities to reduce spoilage, save time, money and energy, and meet safety standards.

High-performance doors safeguard cold storage and food and beverage facilities to reduce spoilage, save time, money and energy, and meet safety standards.

Here are some key safety features to consider when specifying high-performance doors for cold storage facilities.

Rytec has contributed over 35 years of high-performance door innovation to the cold storage and food and beverage industries. Here are 6 notable examples.

How much are older, inefficient doors costing your cold storage facility? Rytec’s new energy analysis can help you quantify these costs.

Rytec’s Sure-Seal® door is designed for AS/RS applications. It can be tightly integrated with warehouse automation systems for maximum efficiency.

Learn how specially-designed doors equipped with touchless activation help to keep clean rooms germ-free for pharmaceutical and food production.

High-performance doors used in cold storage should be inspected quarterly. Here are key areas you should pay attention to during your inspections.

In manufacturing facilities, doors must be reliable for the factory to maintain peak efficiency. Here’s how high-performance doors help.

Cold storage facilities are getting taller to reduce their real estate footprint. So are the high-performance doors used to keep them running efficiently.

High-performance doors used in cold storage, food and pharmaceutical production must meet strict FDA and cGMP regulations. Here’s what you need to know.

High-performance doors deliver reliable performance. That’s because they’re built for longer life expectancy than conventional doors. Here are 4 examples.

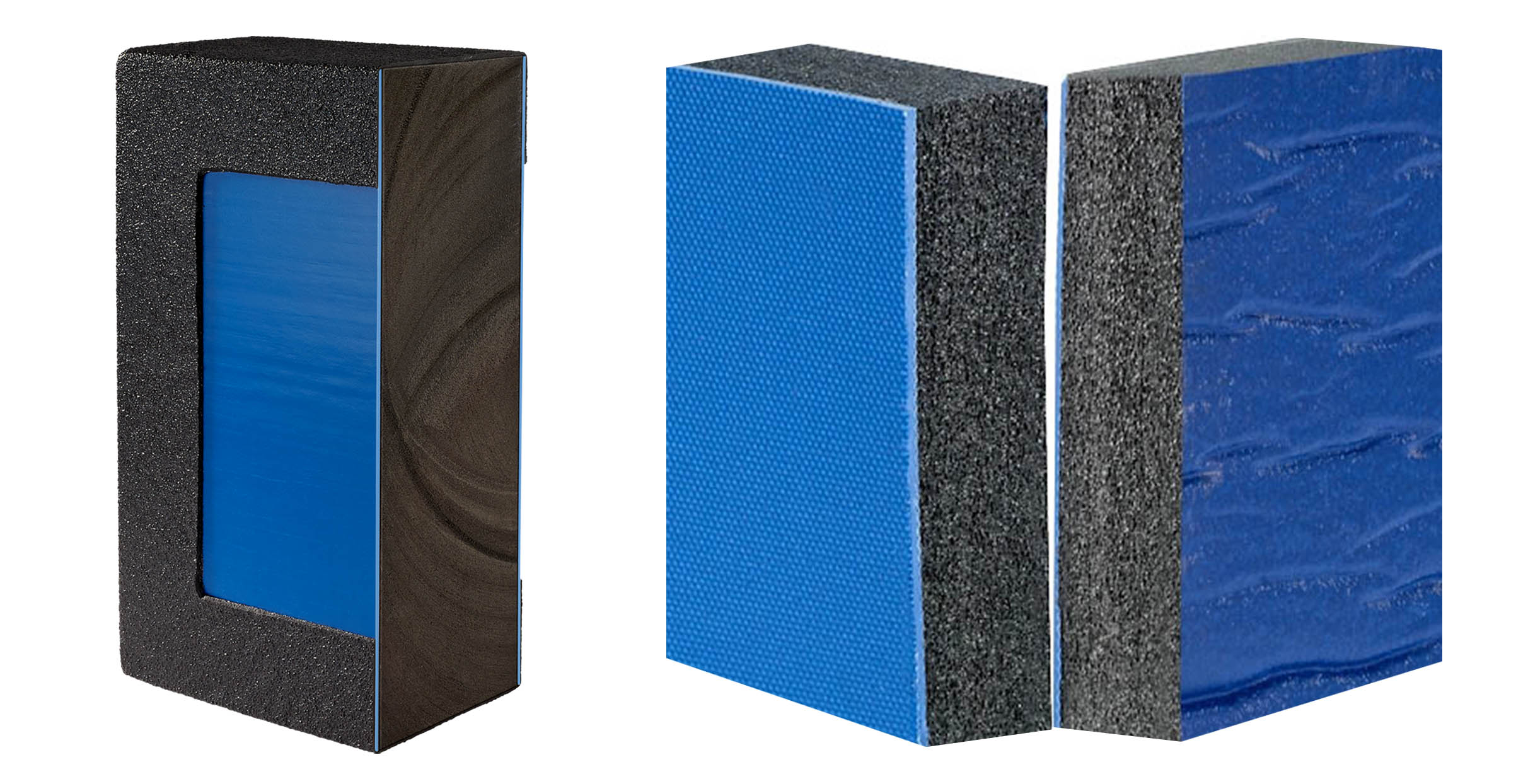

Understanding the R-value of doors is critical in the cold storage industry, where minimizing heat loss and maximizing energy efficiency is a must.